TESTBED FOR REVOLUTE JOINTS WITH CLEARANCE

| Concept | Alessandro Tasora |

| Team | Applied Mechanics Group, Prof.Edzeario Prati |

| Device designer and users | Matteo Toracca, Vincenzo Cero, Fabio Ghellere. |

| Lab | UniversitÓ degli Studi di Parma |

Abstract

Clearances in joints can be sources of noise, vibrations, wear and loss of precision. In order to study this effect from an experimental point of view, we designed and built a four-bar mechanism exploiting a replaceable revolute joint between rod and rocker. Such joint can be mounted in various configurations, with varying degrees of clearance.

We mounted accelerometers on the rod and on the rocker, and compared the resulting data with computer simulations, performed using a novel multibody model targeted at a precise reconstruction of backlash effects. These result matched, and validated our model.

Also, we studied the wear of the bearings in the revolute joint, either with micrometers and with 3D surface acquisition. We developed a numerical model which can predict these effects using multibody simulation.

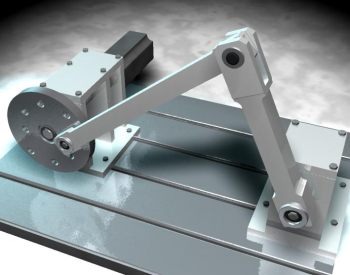

The mechanism has been designed with a 3D parametric CAD. This is a frame from a simulation performed with my multibody software CHRONO

Part of the test bed. Note the LENZE motor on the left, which rotates the flywheel

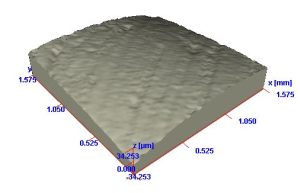

Surface of bearings after thousands of revolutions.

Surface of a bearing after thousands of revolutions (zoomed-in)

Download the article, presented at the AITC 2004 conference

Download the article, presented at the AIMETA 2003 conference